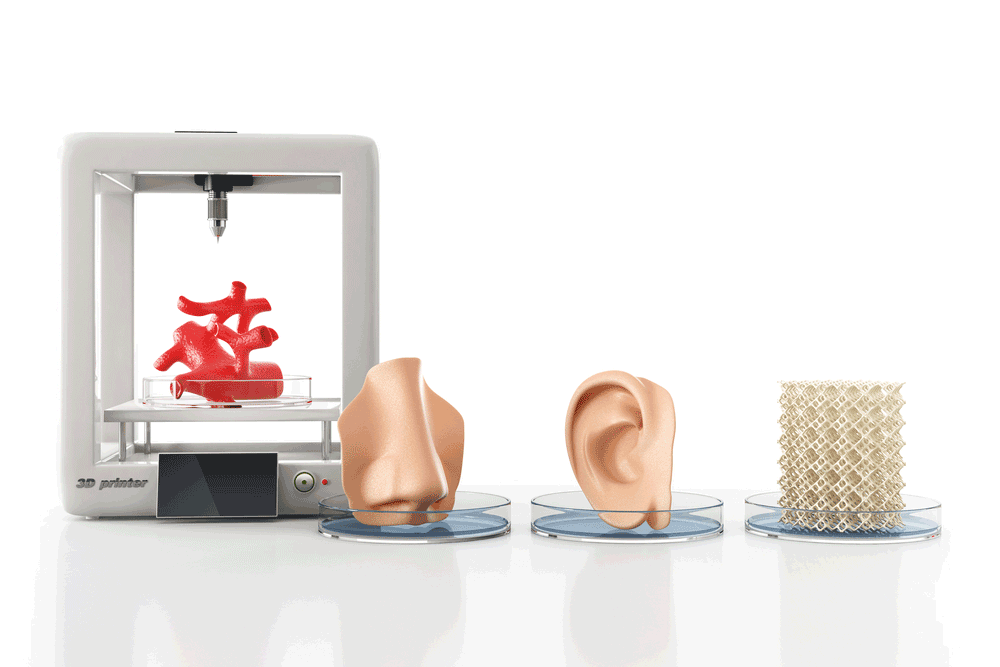

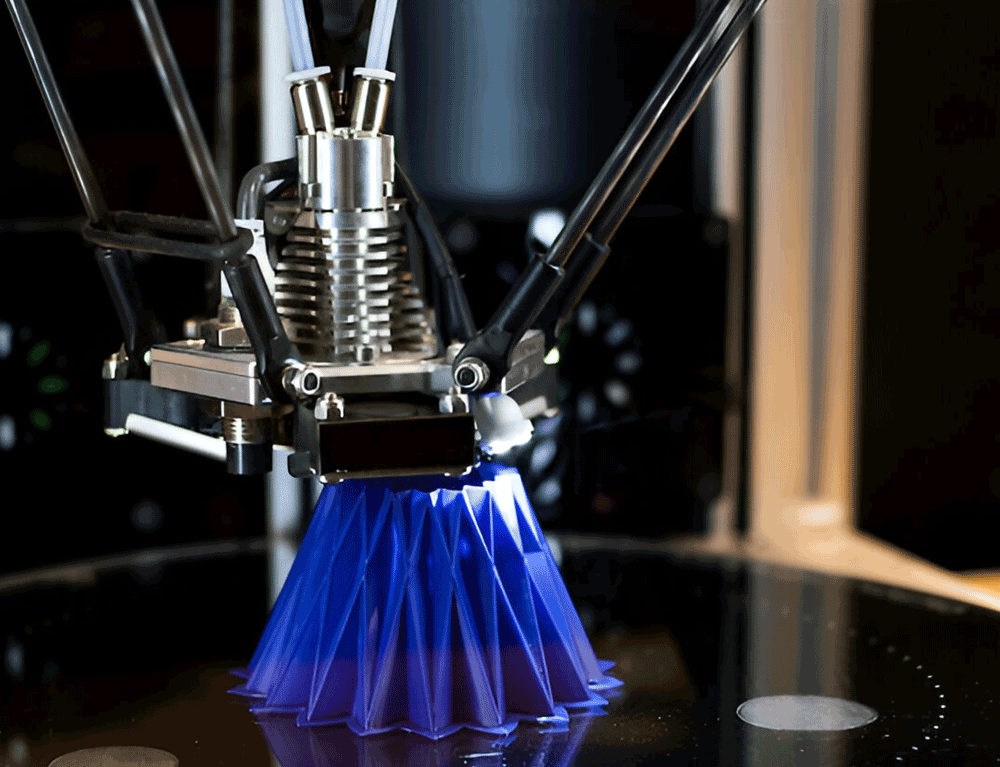

Welcome to Quick Shape's Stereolithography (SLA) 3D Printing Services, where precision, intricacy, and speed combine to create stunning 3D prints that defy convention. SLA technology is renowned for its ability to produce highly detailed, complex, and functional prototypes and end-use parts with exceptional accuracy. Explore the world of SLA with Quick Shape and witness the transformation of your ideas into tangible reality.

Stereolithography, often referred to as SLA, is an advanced 3D printing process that operates on the principle of photopolymerization. In this process, a liquid resin is selectively cured layer by layer using an ultraviolet (UV) laser or light source, solidifying the resin and gradually building the final object. SLA is celebrated for its precision, fine details, and suitability for intricate designs.

Quick Shape's SLA 3D Printing Services cater to a broad spectrum of industries, including:

The applications of SLA 3D printing are diverse and include:

Create prototypes that closely mimic the final product for testing and validation.

Produce intricate architectural models, figurines, and artistic sculptures with fine details.

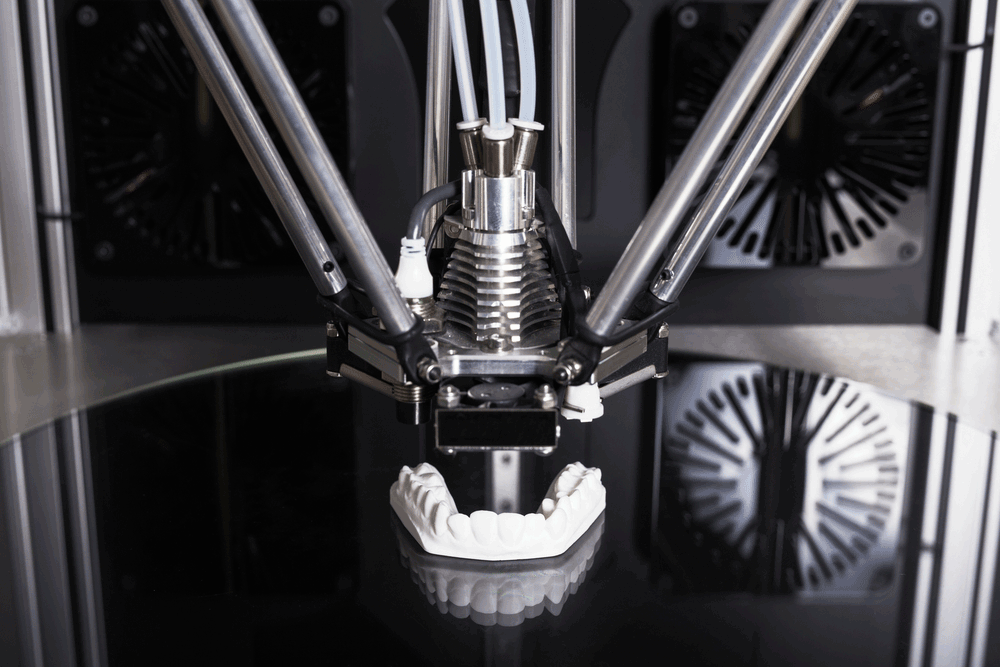

Develop anatomical models for surgical planning and educational purposes.

Craft detailed and personalized jewelry pieces with precision.

Ready to explore the world of SLA 3D printing? Contact Quick Shape to discuss your project, request a quote, or learn more about how SLA can bring your designs to life with unparalleled precision. Our team of experts is here to guide you through the process and help you realize your vision with the precision and intricacy that SLA technology offers. Elevate your projects with SLA 3D printing services from Quick Shape. Let's bring your ideas to life, layer by meticulous layer.

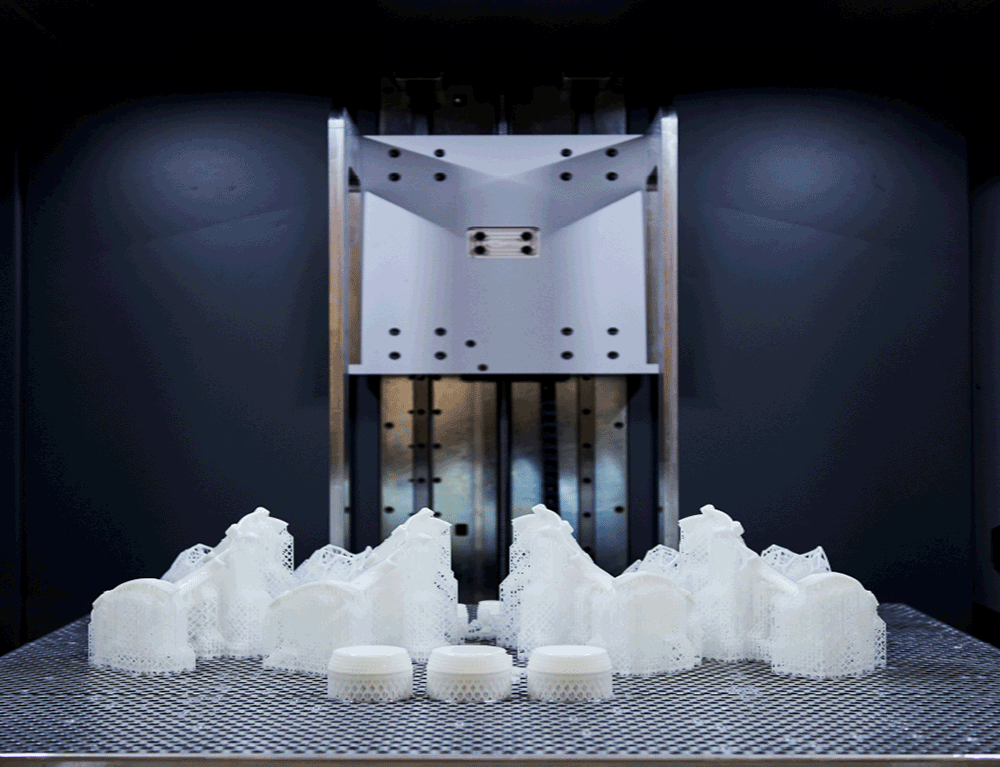

Welcome to Quick Shape's Selective Laser Sintering (SLS) 3D Printing Services, where innovation meets durability and precision. SLS technology is at the forefront of additive manufacturing, known for its ability to create strong, functional, and intricate 3D prints suitable for a wide range of applications. Explore the world of SLS with Quick Shape and discover how this technology can elevate your projects to new heights.

Selective Laser Sintering, or SLS, is a revolutionary 3D printing process that transforms fine powder materials into solid objects, layer by layer, using a high-powered laser. This process allows for the creation of complex geometries, robust parts, and functional prototypes with a high degree of accuracy. SLS is renowned for its strength, versatility, and ability to produce parts with minimal post-processing.

Quick Shape's SLS 3D Printing Services are trusted by various industries, including:

The applications of SLS 3D printing are diverse and include:

Develop functional prototypes that withstand rigorous testing and real-world conditions.

Manufacture durable, end-use components that meet industrial standards.

Assemble intricate and multipart designs with ease.

Create one-of-a-kind products tailored to your exact specifications.

Ready to experience the power of SLS 3D printing? Contact Quick Shape to discuss your project, request a quote, or learn more about how SLS can take your designs to the next level in terms of strength and precision. Our team of experts is here to guide you through the process and help you realize your vision with the durability and intricacy that SLS technology offers. Elevate your projects with SLS 3D printing services from Quick Shape. Let's bring your ideas to life, layer by resilient layer.

Welcome to Quick Shape's PolyJet 3D Printing Services, where innovation takes shape with remarkable precision and detail. PolyJet technology is a game-changer in the world of 3D printing, allowing us to produce highly detailed, multi-material prototypes and end-use parts with exceptional realism. Explore the incredible capabilities of PolyJet with Quick Shape and elevate your projects to new levels of sophistication.

PolyJet is an advanced 3D printing technology that employs inkjet-style printheads to precisely deposit layers of photopolymer resin, which are instantly cured using UV light. This process enables the creation of parts with multiple materials, colours, and fine details in a single print. PolyJet is renowned for its ability to produce realistic, functional prototypes and complex geometries.

Quick Shape's PolyJet 3D Printing Services cater to a wide spectrum of industries, including:

The applications of PolyJet 3D printing are diverse and include:

Bring design concepts to life with vivid and detailed 3D printed models.

Test and validate prototypes with realism, ensuring they meet design and functionality requirements.

Simulate real-world conditions with highly detailed models for research and testing.

Create personalized and visually appealing consumer products.

Ready to explore the world of PolyJet 3D printing? Contact Quick Shape to discuss your project, request a quote, or learn more about how PolyJet can transform your designs with precision and realism. Our team of experts is here to guide you through the process and help you achieve remarkable results with the versatility of PolyJet technology. Elevate your projects with PolyJet 3D printing services from Quick Shape. Let's bring your ideas to life, layer by intricately detailed layer.

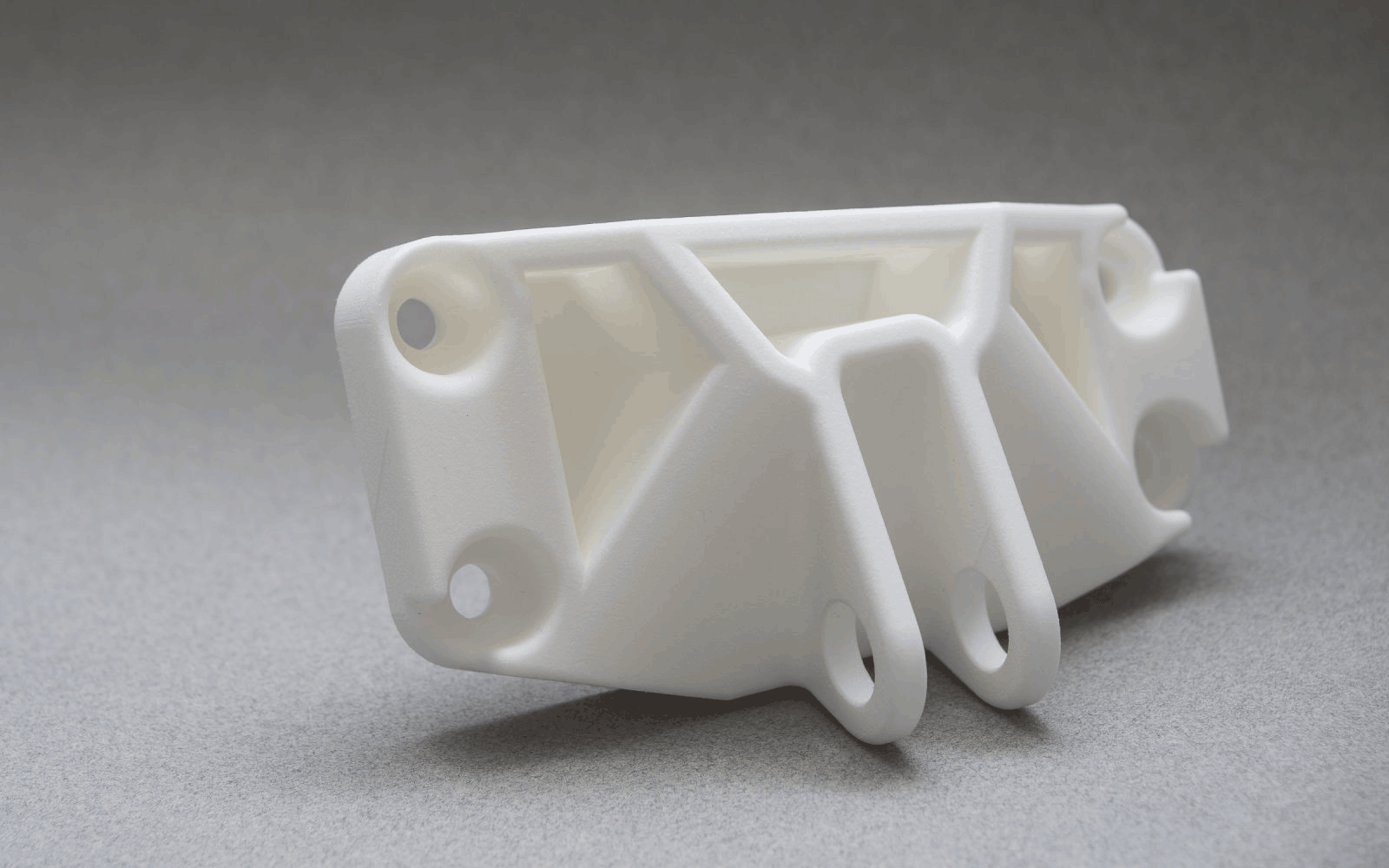

Welcome to Quick Shape's MJF (Multi Jet Fusion) 3D Printing Services, where innovation meets high-speed precision. MJF is a cutting-edge 3D printing technology that offers exceptional speed, fine detail, and versatility. Dive into the world of MJF with Quick Shape and discover how this technology can revolutionize your projects.

Multi Jet Fusion (MJF) is a state-of-the-art 3D printing technology that utilizes inkjet printing and powder fusion to build highly detailed, functional parts layer by layer. It employs a fine powder material, a fusing agent, and a detailing agent to produce parts with remarkable precision, speed, and reliability. MJF is known for its suitability for end-use production and rapid prototyping.

Quick Shape's MJF 3D Printing Services cater to a wide array of industries, including:

The applications of MJF 3D printing are diverse and include:

Develop prototypes for testing and validation with speed and precision.

Manufacture end-use parts with accuracy, durability, and consistency.

Create intricate, detailed parts that would be challenging to produce with traditional manufacturing methods.

Fabricate custom tooling, jigs, and fixtures that streamline manufacturing processes.

Ready to harness the speed and precision of MJF 3D printing? Contact Quick Shape to discuss your project, request a quote, or learn more about how MJF can accelerate your designs and production processes. Our team of experts is here to guide you through the process and help you achieve remarkable results with the efficiency of MJF technology. Elevate your projects with MJF 3D printing services from Quick Shape. Let's bring your ideas to life, layer by precisely fused layer.